Air Handling Unit Upgrade / Refurbishment

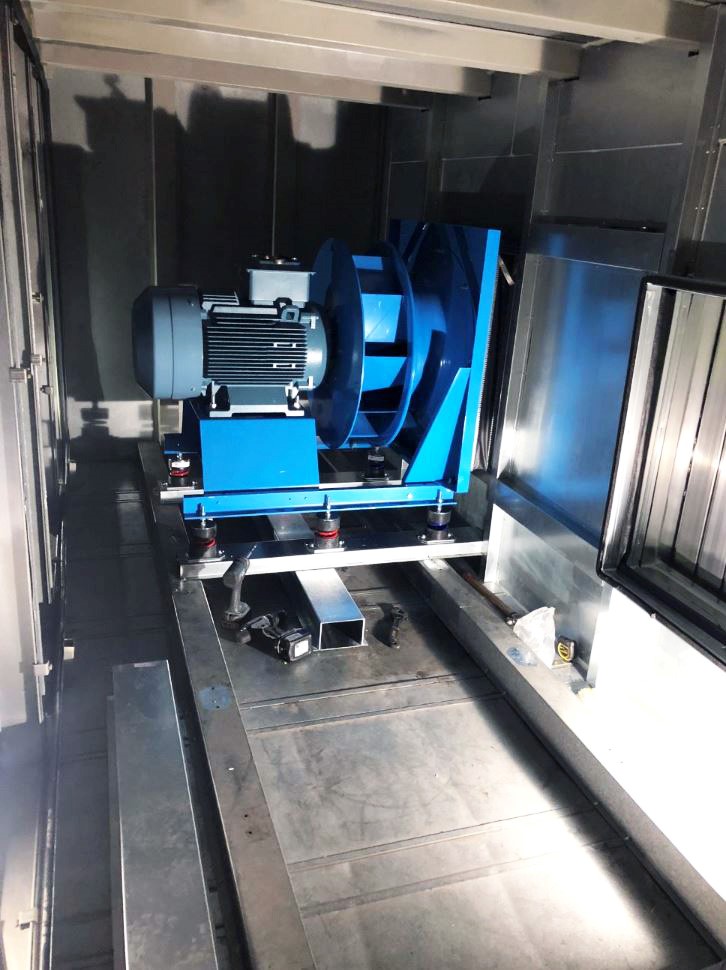

Fan or motor upgrades, save energy, save money

The energy consumption of HVAC equipment can often account for more than 40% of a commercial building’s energy consumption. Simple AHU maintenance improvements to the efficiency of installed systems can offer considerable energy and CO2 savings to the application.

Many options exist to minimise energy consumption by replacing older less efficient fans and motors. Options include:

• Direct motor replacement with current high efficiency AC motors, which can alone provide energy savings of around 20%.

• Replacement of older less efficient forward curved fans with high efficiency backward curved or aerofoil blade fans.

• Modification of energy inefficient and costly maintenance belt drive fans with modern direct drive fans, either AC or EC, with suitable speed control.

Our Research and Development teams have conducted studies to determine which fan and motor combination can provide the most efficient solution for all applications.

In some cases installations have shown that replacing AC fans with an EC fan upgrade allows you to optimise your air handling unit for ultimate energy efficiency, potentially reducing energy usage by up to 70%.

By adding variable-speed AC or EC fans to the Air Handling Units (AHUs), we predict that you can save between 30 and 60% on annual electricity costs. There are still thousands of low efficiency AC fans installed in Air Handling Units throughout the UK.

EC fan upgrades – the benefits

EC fans offer enhanced control and provide the most simple, but effective solution for reducing AHU energy consumption. EC fans today are focused on maximum energy-efficiency to enable equipment used in ventilation to work as economically as possible. Setting new standards with regards to reliability, service life and energy consumption. EC fans are fully compatible with most units, meaning that straight-forward, cost-effective EC fan upgrades can be carried out with minimal disruption.

• Up to 70% potential energy saving

• Variable speed control matched to load

• Direct drive motors for maintenance free operation

• 50% more efficient than previous generation fans

The right fan for your application

There are many factors essential in selecting the ‘right’ fan for your application.

Operating Point:

We will work with you to find out what your operating point is. This is the target air flow rate in cubic feet per minute and a system resistance (or impedance) in inches of water. The target flow rate is usually a known value but the system resistance or impedance is not always available. Knowing the operating point is essential in selecting the correct fan.

Flow Path:

Selecting a fan based solely on the operating point will not necessarily lead to the best results; the path that the air must take through the system must be factored into your fan selection as well. The impact that the air flow path has on a fan’s selection can be dramatic – it can make a very efficient fan perform very poorly and so we work with you to select the optimum fan.

Design Goals:

While the operating point defines the most important variable, power consumption and dependent on application, noise reduction are huge drivers. When noise is a critical factor, the best solution is typically a larger fan running at the lowest possible speed.

Space constraints:

Selection of the right fan must consider the available space within the application. The most efficient or quietest fan may not fit within the available space.

Fan selection can never be viewed as a one-size-fits-all approach. It’s really a compromise between variables. The key to success in finding the right fan is to identify which model results in the fewest compromises.

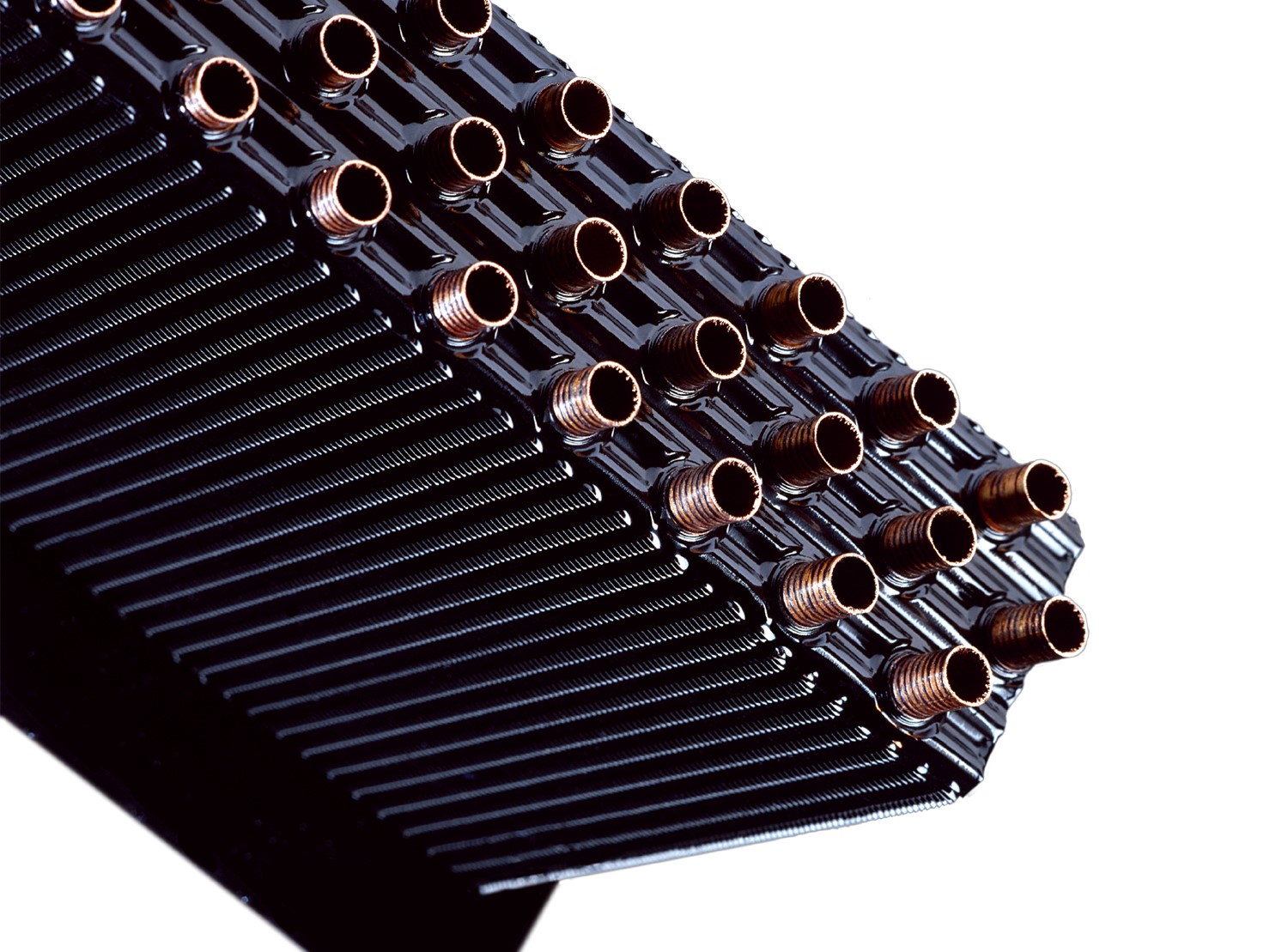

Extend the life of heat exchangers in your Air Handling Units

Key components of HVAC systems such as heat exchangers, evaporator coils and coils in outdoor units are at continuous risk of severe corrosion due to weather conditions and pollution.

Corrosion is the number one cause of efficiency loss in the heat exchanger.

Heat exchangers and coils are made using aluminium, which is relatively corrosion resistant even without any type of coating. However, the harsh conditions in certain AHU Applications often require additional protection, these include:

• Offshore applications

• Coastal applications

• Power plants

• Industrial environments

• Urban dense applications

• Any area to have high levels of airborne pollutants

There are many airborne substances and atmospheric influences that shorten the life of heat exchangers; these include corrosive salts, acids, bases, and/or other chemicals.

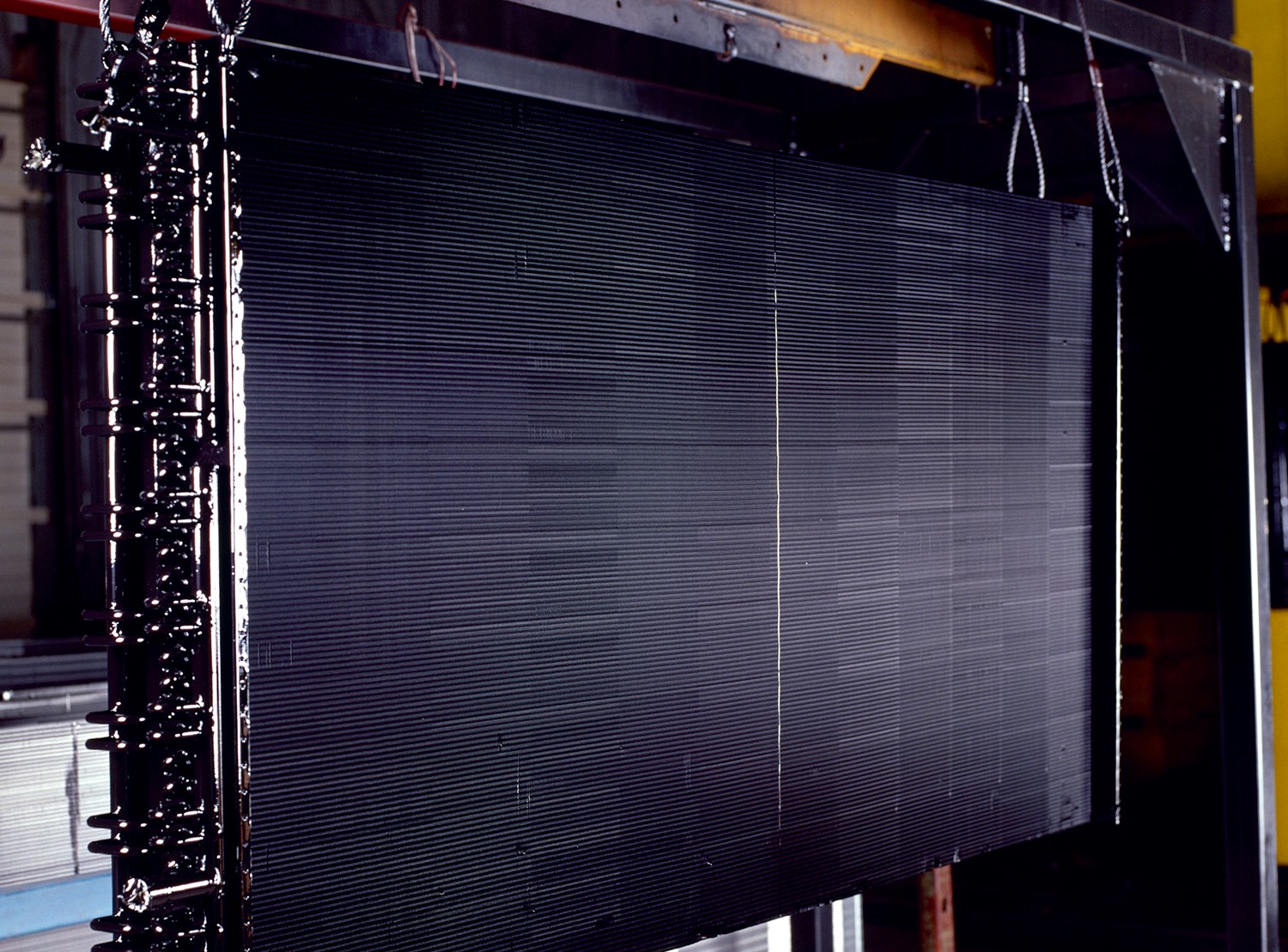

Long lasting anti-corrosion treatment

Airedale provides a long lasting anti-corrosion treatment for heat exchangers. This preventative process seals off the heat exchanger from the environment, without affecting heat transfer and pressure drop.

The process can be applied to new units as well as on-site via our Coil Protection service through our nationwide network of expert service engineers. It can also be applied to both Airedale and third party manufacturer equipment on site and can be applied to any type of heat exchanger/coil.

Why protect?

• It can triple the lifetime of the heat exchanger

• Prevents early deterioration, capacity loss and the need for coil replacement

• Potential annual savings of up to 30% on energy costs

Keep coils clean and improve air quality and system performance with UV cleaning

Keep coils clean and improve air quality and system performance with UV cleaning

In the wake of the Covid-19 pandemic, many companies are now more concerned about the safety of occupied buildings. In response, Barkell have launched LightGuard, a UV coil cleaning solution, which disinfects systems and prevent the build up of biofilm, a sticky, microbial mass found on HVAC coils, drain pans and ductwork.

The cost of dirty coils is high:

- HVAC systems can account for up to 60% of a building’s energy costs

- Dirty HVAC coils waste an additional 25% energy

- The percentage of indoor air quality problems related to HVAC (absenteeism, productivity) stands at approximately 75%

- 60% of indoor spaces are hazardous to their occupants’ health due to air pollution

How does LightGuard work?

A LightGuard UV-C coil cleaning system can be fitted in just about any new or existing air handling unit. The UV-C lamps (number depends on the size of the equipment and type of installation) are installed downstream of the cooling coil and use a photon concentrator which focuses up to 95% of the UV energy produced onto the coil.

Applying UV-C to a cooling coil will effectively disinfect the surfaces of equipment, removing harmful organisms before they potentially enter the airstream.

The lamps prevent the build up of biofilm, a sticky microbial mass found on HVAC coils, drain pans, and ductwork. It is secreted by communities of microorganisms, bacteria, moulds, and fungi that naturally gather in HVAC systems.

Biofilm, when allowed to build up, acts as an insulator, reducing the efficiency of heat exchange. It fills interstitial spaces, increasing pressure drop across an HVAC coil and it produces sulfite-reducing bacteria, causing corrosion to an HVAC system. The air passing through a contaminated HVAC system will pick up bacteria, moulds, and other infectious particles and distribute them throughout the building.

Biofilm is resistant to physical cleaning and chemical disinfectants so preventing its build-up in the first place is a real advantage. LightGuard has been proven in multiple applications to reduce this build-up and preserve system performance.

What is UV-C effective against?

• Bacteria such as listeria, MRSA, E-coli, Legionella

• Fungi such as yeast and mould

• Viruses such as Influenza, Norovirus and Coronavirus

Cleaner Systems

UV disinfectant solutions reduce microbial contamination within HVAC systems by more than 90%

Improve Health

HVAC disinfectant solutions which rely on UV light lower respiratory illnesses among occupants by more than 40%

Future Proofing

UV coil cleaning is a natural solution to the problem of drug-resistant and chemical-resistant infectious diseases

What are frost coils?

Units that are subject to freezing temperatures will typically have frost coils fitted, to protect them from the elements. However, these coils need regular maintenance to ensure they remain functional.

Why do they need changing?

Older frost coils on AHUs can and often do burst in winter, causing disruption and discomfort to the building that the AHU is serving. This can be really problematic, especially within healthcare and other critical environments. Coils can be changed on site as part of planned works to minimise the chances of disruption during winter months.

When is the best time to change them?

Frost coils can be changed at any time, but doing this in a breakdown situation, potentially in freezing or wet conditions, just adds to the stress of a situation. We recommend checking coils at a time when a planned change can be facilitated with the least disruption to your building.

How do I arrange to check or change my frost coils?

We can arrange a survey and/ or provide a quote for any make or model of air handling unit, it doesn’t need to have been supplied by Airedale.

Keep coils clean and improve air quality and system performance with UV cleaning

Keep coils clean and improve air quality and system performance with UV cleaning